Estimates vary but more than two thirds of the world’s populations will be living in cities by 2050 – an increase of 13%, equating to roughly 1bn more people. As things stand, this poses a number of issues not least for air quality and noise pollution as scores of vehicles flood the cities to meet our needs whether it is for construction materials and equipment or goods for home delivery and healthcare.

While much of the urban population growth is expected in countries such as India, China and Nigeria, Europe and the UK are reacting to the role transport plays in pollution levels and are introducing stricter emission targets in cities and placing restrictions on the types of vehicles that will be allowed to enter the cities to counteract the rise.

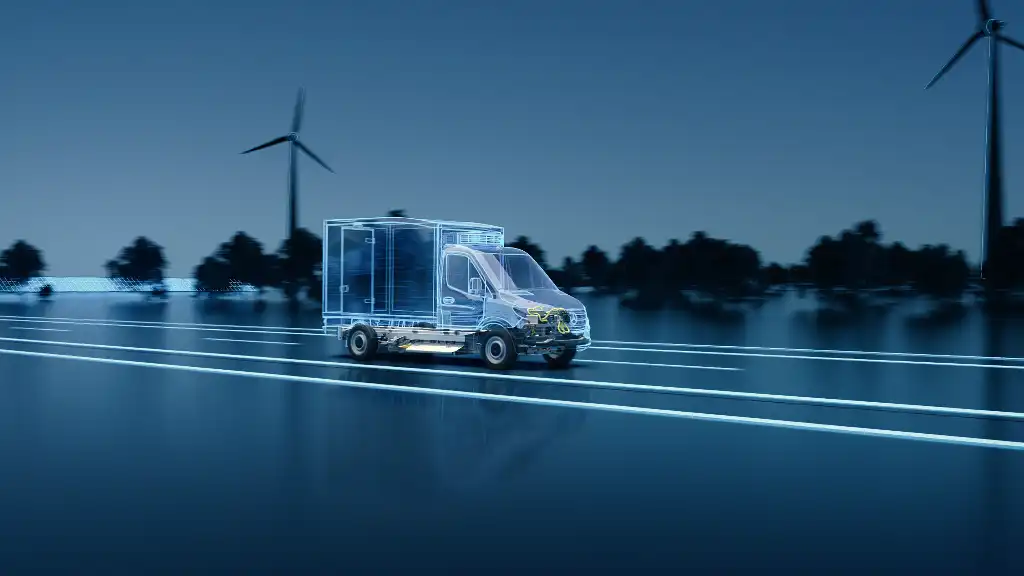

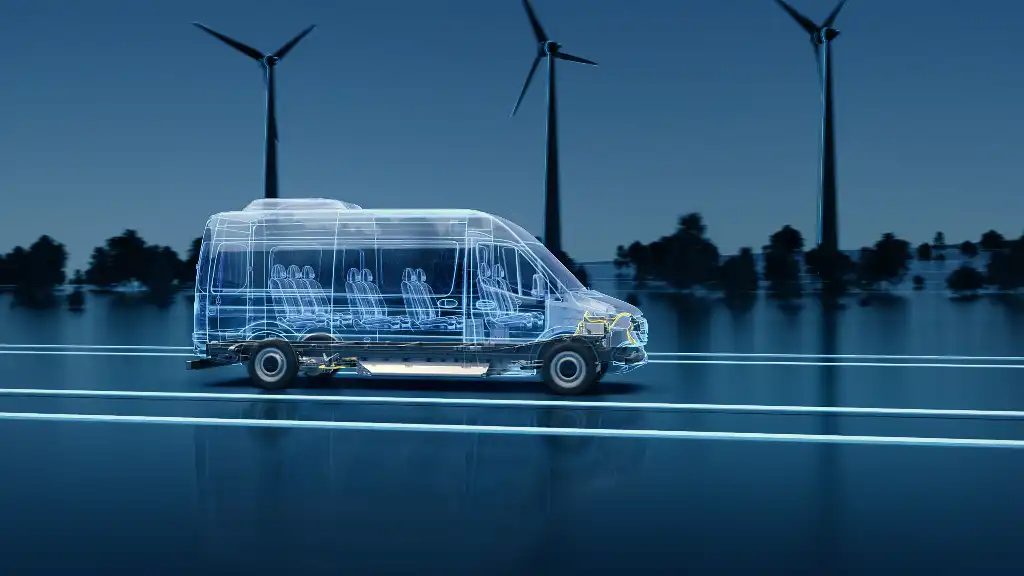

Electrification is becoming a high priority for governments and fleets alike, but how will building materials, your weekly food shop and critical temperature vaccines all be moved about the urban environment. There’s now a growing need for converted electrified vehicles capable of moving such items and just like with combustion engine products it will be chassis cab vans from bodybuilders that will be filling the void.

“We’re constantly electrifying our vans, and we always keep an eye on our customer requirements. The requirements regarding bodies and conversion are as diverse as the sectors that use them,” explains Markus Reis, Mercedes-Benz Vans product manager.

While there are no limitations as to where an electric vehicle might be used and what sectors are likely to operate them first, blue chip companies are leading the way and it’s no surprise that the booming home delivery segment is a willing customer.

“We have both N1 and N2 vans of the E Deliver 9 being built for Tesco,” explains Mark Barrett, MAXUS general manager. Having already supplied chassis cab versions of its previous generation large electric van, the EV80, to a number of fleets, MAXUS has been able to develop their new E Deliver 9 model to better cope with the demands imposed by fridge units, tail lifts and other auxiliary equipment.

“One of the things for us, is the early planning with the customer at how we integrate the fridge and the base vehicle together. We engage with the factory, and we have 3kW to 5kW of additional spare power from the battery which is going through a controller unit, and the fridge connects to that. For other auxiliary equipment, like tail lifts, it can come from the standard 12v battery,” explains Barrett.

Not all manufacturers will permit a direct power feed from the traction battery, which can lead to having separate power supplies in addition to the 12v battery to run ancillary devices, however, for the most part the power consumption of the equipment is either relatively low, or confined to short bursts.

“Of course it impacts on the range,” continues Barrett, “but surprisingly very little. On maximum drawdown you’re looking at 10 to 15 minutes to get it down to chill or frozen. That will probably done while still on charge and once its down to temperature it doesn’t take much [to maintain the temperature]. Heating the cabin of the van will in theory use more van than the fridge.”

Veteran of the electric light commercial vehicle market Renault, whose Master ZE large van has recently been rebranded as the Renault Master E-Tech, already has an electric Luton low-loader van on sale and is, according to Renault LCV conversions manager Mark Waite, experimenting with other prototype bodies and battery top-up solutions.

“The only complexity we have with electric vehicles is how you treat electrical connections because it’s forbidden to take any electrical connections off of the Master’s traction battery. You still have the 12v electrical system to connect to, so the question is when do you connect to that [or a separate supply]. We’ve prototyped a ZE tipper and will go into a test phase to see what impact it has on range. We’re not expecting it to have a dramatic effect because the electrical draw for raising a tipper bed happens for a 20-second blast. Putting a tail lift on a Luton box van, you’ve got the same issue where the electrical draw would impact the range of the vehicle. In that instance, we’re doing a trial with fitting solar panels to the roof to assist in making sure the main 12v battery is topped up, because in reality you’re going to use a tail lift more than a tipper.”

Manufacturers are in fact already working on a solution for more power-hungry equipment with both Iveco and the Stellantis brands confirming to Van Reviewer that they are working on electric PTO solutions for their eLCVs.

“We’ve been working with bodybuilders for about two years,” says Mike Cutts, Iveco business line director (LCV) about the 2022 model-year electric Daily van.

“We will focus on the chassis models with an electric PTO offer, making sure there’s enough transferable power to meet the applications whatever you want to put on the back,” Cutts explains.

Presently, however, Stellantis bodybuilder relations manager, Hervé Criquy, believes that the vehicle’s main battery can be used to power most equipment and with only a small decrease in range from the equipment’s power draw. “We believe the HV (high voltage) battery can supply enough power to any conversion appliance, without major impact on the range due to the consumption. For example with fridge solutions, the impact of a normal delivery round trip shall be of -5 to -8% on the range,” Criquy says.

When it comes to limitations on what body can be applied to an electric van both Barrett and Waite believe there are actually no limits. With the exception of the placement of battery cells if they’re located within areas a bodybuilder would want to drill in to for mounting, neither sees any issues – a point which Mercedes has ably demonstrated by converting an ambulance on to an Mercedes-Benz eSprinter chassis.

“The industry is quite good at thinking how to overcome potential drawbacks with electric systems. If you think of refrigerated vehicles, the refrigerated vehicle industry has developed its own lithium-ion battery systems to power electrical refrigeration units,” Waite says.

Barrett agrees, and goes so far as to say that electric versions can outperform their diesel equivalents.

“I think any of the applications on a diesel would work on electric. Even when it comes to van payloads as we have that flexibility in the UK with the uprated payload. It has killed that issue. We’re plated at 4050kg on the N2, so you’ve actually got a better payload.”

Vehicle range, reduced payload and invariably the purchase cost may all be valid areas of concern for potential electric van purchasers, but when it comes to equipping this new era of vehicles with the bodies and equipment we’ve become accustomed to there’s no reason to be alarmed. Indeed, as technology improves, the efficiency and productivity of these vans may well see bodied EVs becoming more practical and cheaper to run than their ICE equivalents.

How to build onto an electric van chassis

Like with any build its best to read the instructions. Manufacturers provide their partners with details technical documents and these should be your first port of call. An accredited body builder is best placed to do the work. If in doubt, consult the experts.

The priority is to not damage the safety cell of the vehicle or its battery. Many electric vehicles have defined points where bodies, cranes or tail lifts can be fixed to. These will likely be the same position as any ICE equivalent vehicle.

If adding additional powered equipment don't assume you can use the van's own electrical system. Some vans will make provisions for you to tap into an electricity supply, other won't. More power hungry devices might require a Power Take Off unit and ePTOs are becoming increasingly common.