Home »

Mercedes-Benz dealership group Intercounty Truck & Van has announced a £2m investment in a new service and parts centre located in Dunstable, Bedfordshire.

The new facility boasts a modern workshop designed to service and maintain Mercedes-Benz vans as well as those of all other makes and is expected to create 30 new jobs in the local area.

Customers will also have access to a parts counter and a range of electric vehicle (EV) support features, including eight dedicated EV charging points.

Located on the Woodside Industrial Estate, it's close to the M1 motorway (J11 and 11a) as well as London Luton Airport. The center aims to minimise downtime for van operators and disruptions in the local area with swift assistance for its customers.

The investment extends beyond the physical facility with Intercounty Truck & Van recruiting apprentices and providing comprehensive training programs for technicians.

The training program is said to exceed industry standards by allowing technicians to specialise in servicing electric vehicle components, including batteries for the new Mercedes-Benz eSprinter.

Nick Skillman, MD at Intercounty Truck & Van, said: “The launch of our new Dunstable site offers incredible opportunity, both for us as a business and for the local economy – particularly as we welcome the transition to electric.

“We’ve been operating as a Mercedes-Benz franchise for over 20 years, covering Northamptonshire, Cambridgeshire, Buckinghamshire and Lincolnshire.

“Now, we have a new, state-of-the-art dealership with huge market potential that sits in a prime location in Bedfordshire – a stone's throw from the M1 and around the corner from our customers at Luton Airport, which is set to double in capacity over the next 20 years.

“The new dealership has been built to meet the demands of loyal customers in the area as well as an engaged local community that is committed to being more sustainable – and we couldn’t be more excited for its launch.”

Simon Neill, customer operations director at Mercedes-Benz Vans in the UK, said: “Intercounty Truck & Van has been a trusted partner of Mercedes-Benz Vans for over 20 years and we are delighted to support the launch of this new, exciting Customer Service and Parts location.

“It is set to provide customers and those travelling up and down the M1 with a huge range of services, parts, electric vehicle expertise and roadside assistance cover to ensure that the Intercounty team continue to keep businesses moving with reliable and sustainable transport.

“We’re also incredibly pleased to see Intercounty Truck & Van investing in 30 more roles that will bring new talent and skill sets to the Mercedes-Benz Vans brand network.”

Mercedes-Benz Vans has updated its Sustaineer project with a new e-cargo bike to accompany the Mercedes-Benz eSprinter based van.

The Sustaineer eSprinter van was first introduced in 2022 as an example of the work Mercedes is doing to use more sustainable materials in its production models. The latest iteration takes that concept and adds a new e-cargo bike to urban deliveries.

In cooperation with a Berlin-based cargo bike manufacturer, ONOMOTION, the van and bike show how the two can work together in a hub and spoke approach to last mile deliveries.

Mercedes says the eSprinter will become a mobile micro-depot bringing pre-packaged goods in special containers to cargo bikes. The e-bikes will then take deliveries direct to the door of customers. This, they say, will enable the eSprinter to spend less time standing idle at the kerb and it can instead carry on its way, improving delivery efficiency.

The concept is said to be suitable for a wide range of industries from courier, and parcel services to food and even textiles.

The consignments can be pre-picked a base ahead of the delivery route and then loaded into the interchangeable wheeled ONOMOTION containers. The eSprinter van then transports them to the handover point.

Each container has a load volume of more than 2m3 with a payload of up to 200kgs. The container lift works hydraulically, has recessed rollers, and can be controlled by remote, allowing them to be loaded and unloaded quickly and safely.

The large Sprinter dimensions means that are able to fit into a long-wheelbase van, while still leaving enough space for a shelving system – accessible through the right-hand rear door.

The ONO e-cargo bike has a range of up to 25km and uses a 1.4 kWh battery with pull-away assistance of up to 6kmph. It also uses a replaceable battery system to increase range, and requires no driving licence.

The Sustaineer technology demonstrators are currently undergoing intensive testing with a view to possible series production. Features being trailed include heating close to the body and zonal air conditioning to help increase the range of electric vehicles.

At –7C, zonal air conditioning with heating close to the body consumed around 25% less energy than conventional ambient air heating. At +5C energy was reduced by about 50% thanks to heated surfaces in the footwell, the driver's door and on the steering column panelling.

Because only the area around the driver, rather than the entire interior is heated, the air conditioning fan can run at a low level, reducing noise.

The Sustaineer also has a particulate filter integrated into the front module, developed to reduce particulates from tyres, brakes and asphalt wear from getting into the cabin.

There’s also a solar panel on the roof, components made from recycled materials like plastics as well as hemp.

The project is part of Mercedes' ongoing sustainability objectives.

The Sustaineer is just a concept, however, elements from its trails could possibly make an appearance in future Mercedes-Benz van products. The next major update to their product range will be in the introduction of the electric VAN.EA platform, which will form the basis for both future medium and large vans.

The Mercedes-Benz Sprinter is the largest van in the Mercedes range and have a towing capacity to match. In fact, the Sprinter is so good at towing that it can tow an elephant - pictures don't lie.

The majority of Mercedes Sprinter vans have a towing capacity of 3.5-tonnes or 3,500kg (7716 lbs). This is how much weight a Sprinter can tow as a maximum and is applicable for the 3.5-tonne GVW models and larger 5- and 5.5-tonne vans. Smaller vans with a GVW of only 2.8-tonnes can tow just 2-tonnes or 2,000kg (4400 lbs).

The easiest way to check your towing capacity is to look at the vehicle plating weights on the door frame of the van, or under the bonnet. These will tell you exactly what the Sprinter van can tow as well as giving the GVW and the Sprinter payload.

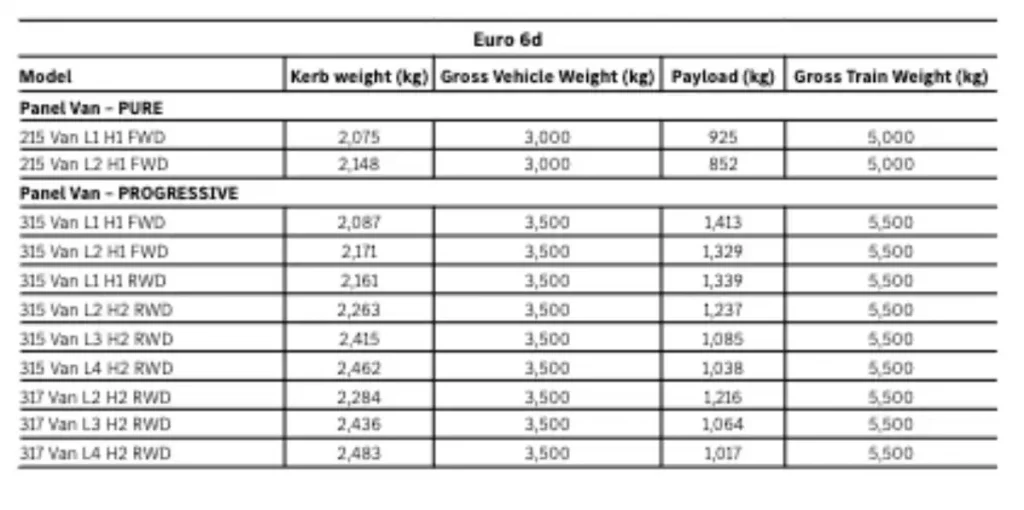

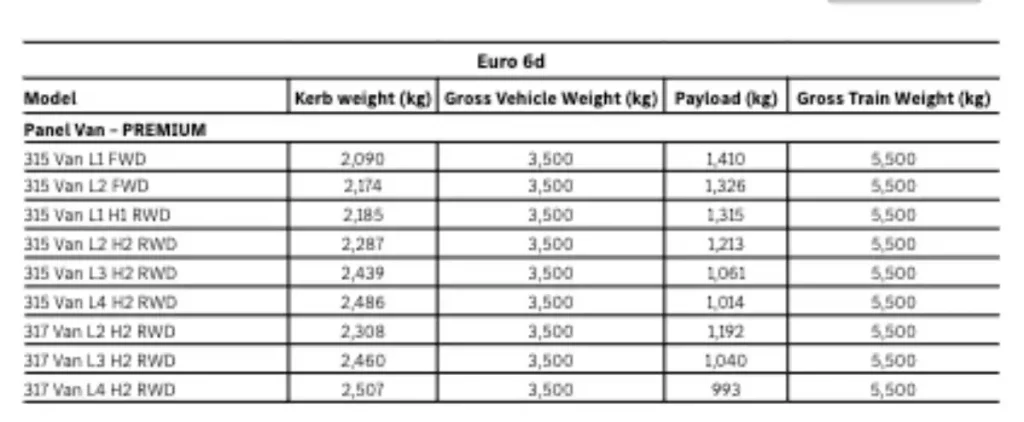

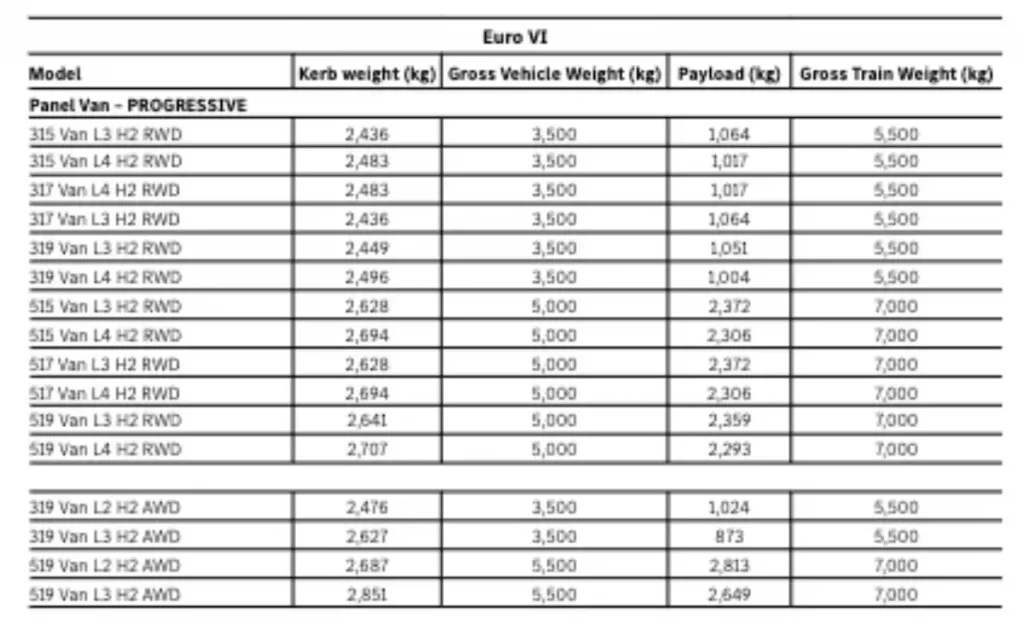

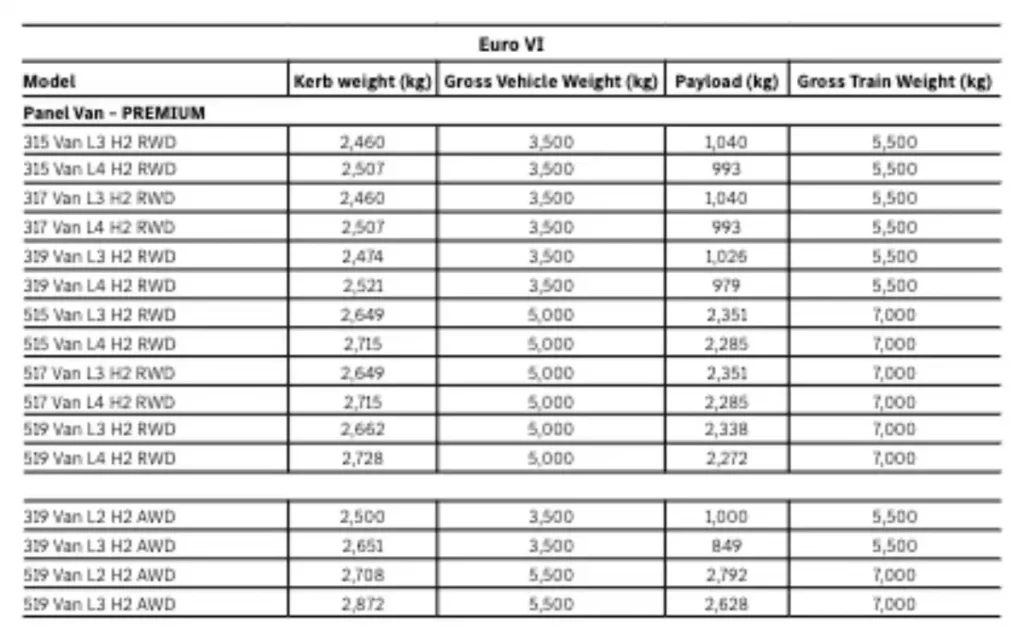

However, the badges on the back of the Sprinter give you a clue as to its size. Mercedes produce models with numbers like the Sprinter 215, 315, 317, 319 and 515, 517 and 519 which denote the gross weights of the vans. The 2xx-series are capable of towing the smaller 2-tonne capacity, while the 3xx-series and 5xx-series can tow the higher weights of up to 3.5-tonnes.

Yes, a Sprinter van could tow a car but it all depends on the maximum weight of the car which will determine if you have exceeded the Sprinter towing capacity. As most cars are under 3.5-tonnes, the majority of cars can be towed by a Sprinter van, but you must also factor in the weight of the trailer (assuming you are using one) and consider the overall gross train weight (GTW) of the van and car combination.

The Mercedes-Benz Sprinter has a gross train weight of up to 7-tonnes or 7,000kg (15,432 lbs). That's for the very largest vans in the 5-series of weight category. The more standard 3.5-tonne vans have a GTW of 5,000kg (11,023 lbs).

So, what is GTW and why does it affect what I can tow?

Well the gross train weight is the total weight of the van plus the weight of anything you are towing.

For example, the easiest way to understand this is to imagine you've filled a 3.5-tonne Sprinter van completely full of weight. The total of the Sprinter, plus fuel, plus your weight, any passengers and whatever you have in the cargo area has an overall weight of 3500kg. In order to not exceed the total allowable GTW of 5500kg you must therefore not tow anything more than 2000kg.

If you want to maximise your towing capacity and tow a full 3500kg - the maximum the Sprinter is safely allowed to tow, so as not to damge the chassis or towing arm - then you'll have to lower the amount of weight you are carrying. To figure out the maximum you can carry it is therefore: Gross Train Weight minus kerbweight = maximum towing capacity.

The tables below will help explain the towing weights for the Euro 6 and Euro VI versions of the Sprinter.

The only Sprinter models capable of carrying the complete 3.5-tonnes are the Sprinter 515, Sprinter 517 and Sprinter 519. Their 7-tonne GTW minus kerbweight of roughly 2.7-tonne (depending on version) is comfortable enough to tow a full weight trailer combination with some payload in the cargo space.

The best of the other models is the Sprinter 315 which can roughly tow 3,400kg. However, that is a front-wheel-drive (FWD) model which may not be most suitable for towing heavy loads. A rear-wheel-drive (RWD) variant would be more suitable and for that you'll need a Sprinter 315 RWD which can tow a maximum of 3,339kg.

No, the Sprinter doesn't come with a tow bar fitted as standard but it is easy enough to specify one from the options list. There are even a couple of Sprinter tow bar types to choose from with a fixed coupling head (c. £650) and a removable trailer coupling ball (£900). You can then decide if the tow bar for the Sprinter needs a trailer socket for a 13-pin electrical system (£300) and there are various enhanced towing capacity options depending on what GVW van you have.

The Sprinter towing eye can be found in the toolkit of the van which is normally located in a drop down panel in the door of the van. In there you'll find the towing eye which needs to be put into the front bumper in order to tow a Sprinter. There's a small square-shaped panel in the lower portion of the front bumper to the side of the numberplate. Pop this cover off using something like a flat head screw driver and simply screw the towing eye into the Sprinter.

The Mercedes-Benz Citan and Volkswagen ID Buzz Cargo have joined the Ford Transit Courier in the highest Platinum safety rating for vans

For the first time, Euro NCAP has released crash avoidance ratings for eight vans. Each are from the small van segment, many of which have an equivalent passenger version.

The Mercedes Citan and VW ID Buzz Cargo received the highest scores, achieving a Platinum rating. The Citan scored a total of 87% acheiving the highest "Good" rating in five out of six categories - falling down on pedestrian safety where it received an "Adequate" rating.

Volkswagen's ID Buzz Cargo scored a total of 83% acheiving a Good rating in four out of six categories, and Adequate ratings for both pedestrian and cyclist safety.

Gold ratings were awarded to the Citroën Berlingo and its siblings the Fiat Doblo, Vauxhall Combo and the Peugeot Partner. Also awarded Gold was the Renault Kangoo Van - makers of the Mercedes-Benz Citan - and the Volkswagen Caddy Cargo.

Unlike Euro NCAP’s car safety rating, the commercial van rating system focuses on crash avoidance technology. This is because when a van is involved in a crash, most casualties are in the opponent vehicle or are a vulnerable road users such as a pedestrian or cyclist.

Euro NCAP introduced new safety ratings for vans in 2022, then updated their requirements when they published a new list of the safest vans in 2023.

Euro NCAP said that it noted that smaller panel vans are better equipped with safety assistance technologies than larger cargo vans. This is largely due to their relationship to passenger cars.

The safety systems Euro NCAP expects to be included in vehicles covers advanced autonomous emergency braking technologies (AEB) for car-to-car, pedestrian and cyclist, lane support systems, speed assistance, as well as attention assist.

From July, van makers will need to ensure N1 category vans have a certain standard of saftey systems fitted.

The UK's appetite for new light commercial vehicles (LCVs) continues to surge, with February witnessing a 2.2% uptick to 17,934 units, marking an impressive 14 months of consecutive growth. Today's figures from the Society of Motor Manufacturers and Traders (SMMT) reveal that this February's performance is the strongest since 1998, despite the month typically being slower due to procurement delays until March for the new numberplate.

Among the standout trends, registrations of vans weighing between 2.5 to 3.5 tonnes soared by 1.4%, representing nearly 70% of all new van sales as the preference for larger units persists. However, the small van categories witnessed declines, with small vans dropping by -20.5% and medium-sized vans seeing a -5.9% dip.

In a surprising turn, the niche 4x4 segment witnessed a remarkable 108.3% surge in registrations, while pickups, vital for rural and construction sectors, secured the third spot in commercial vehicle popularity, registering a 21.2% increase.

Fleet renewal, essential for decarbonisation, received a boost with the government's decision to scrap changes to double cab pick-up vehicle taxation, facilitating investments in newer, lower emission models. However, the sector advocates for a fairer and simpler approach to van taxation based on a vehicle's type approval.

While each manufacturer now faces mandates to achieve a minimum proportion of zero-emission registrations annually, February witnessed a slight decline in registrations of battery electric vans weighing up to 3.5 tonnes like the Ford E-Transit and Mercedes-Benz eSprinter. Maintaining incentives and expanding charging infrastructure, especially tailored for vans, will be pivotal in accelerating demand and achieving net zero targets swiftly.

In a resounding victory for Stellantis, latest figures from the SMMT reveal that almost a third of vans sold in the UK this year bear the badges of Stellantis brands. The automotive giant stands as the leading van manufacturer in 2024, with a 10% surge in volume, now boasting 32.45% of the market share year-to-date.

February saw Stellantis extend its dominance, topping the sales charts with a 7% spike, accounting for 32.91% of van sales. Vauxhall sold an impressive 4,376 units due in part to its noteworthy electric van presence.

Citroën Berlingo emerges as the nation's favorite small van, clinching both February and year-to-date top spots with 2,299 units sold. FIAT Professional also roars ahead with a remarkable 65% surge in February sales compared to last year.

Charging software company Rightcharge is to give Mercedes-Benz van buyers a more affordable and easier service to get their charging solutions sorted.

Rightcharge will give electric van drivers a comprehensive end-to-end solution for charge point installations. They claim it will be 'a hassle-free experience from start to finish'.

Buyers of a new Mercedes-Benz eCitan will get a £1000 contribution towards the cost of installing a charging point from Rightcharge. There's a full range of charge points available from top names which are installed by a network of vetted and monitored installers.

In a release from Mercedes and Rightcharge is says that "the agreement demonstrated a mutual commitment to supporting electric fleets". It goes on to outline that both companies are set to release new products in 2024. Mercedes will launch its updated Mercedes-Benz eSprinter in the UK with a massive 113kWh battery, while Rightcharge is set to launch its own electric fuel card and fleet management solution.

Rightcharge CEO Charlie Cook said:

"We are thrilled to collaborate with a brand that is as loved and respected as Mercedes-Benz as we work closely together to simplify the transition to electric vans. Businesses and van drivers can now find the perfect charge point for their needs in just a few clicks. We're excited to further develop this relationship and create a more sustainable future for Britain."

Sarah Palfreyman, Sales Director of Mercedes-Benz Vans in the UK commented:

“This partnership further cements our commitment to supporting the UK’s van community in transitioning to electric. We know that infrastructure is a vital part of EV ownership, so we’re pleased to partner with Rightcharge to provide a solution that will keep our customers moving efficiently and sustainably.

UK demand for new light commercial vehicles (LCVs) surged by 21.0% in 2023, reaching 341,455 units, as per the latest data from the Society of Motor Manufacturers and Traders (SMMT). Each month, more businesses invested in fleet renewal compared to the previous year, resulting in a record influx of zero-emission vans onto Britain’s roads.

In 2023, an additional 59,316 LCVs of various types and sizes were registered compared to 2022, following a £2 billion increase in spending by companies fulfilling essential roles in the economy, spanning from local trades to online delivery services. December notably experienced a 36.1% surge in demand, marking the strongest month since 2015. As a result of increased vehicle investment throughout the year, 2023 witnessed the highest demand for new vans since the sector’s post-pandemic recovery in 2021, with the market just -6.6% below 2019 levels.

Demand for the largest vans (weighing more than 2.5 tonnes to 3.5 tonnes) continued to rise by 9.4%, representing 66.9% of all new van registrations, driven by operators opting for payload efficiencies. Medium-sized vans (above two tonnes to 2.5 tonnes) saw the largest growth, surging by 78.4% to 57,992 units, catering to urban operators' requirements for heavy load carrying capacity and smaller vehicle sizes.

New battery electric vans (BEVs) witnessed a positive trend, reaching record volumes with a 21.0% increase to 20,253 units, constituting 5.9% of the market. December saw a remarkable 73.8% surge in BEV uptake, with the greenest vehicles representing 10.0% of registrations, marking the second-highest monthly BEV share.

The Ford Transit Custom was the best-selling model of the year, followed by its larger sibling the Ford Transit dimensions. Third place in the rankings went to the Vauxhall Vivaro dimensions and the first and only pick-up truck in the top ten was the Ford Ranger.

Despite these advancements, the Zero Emission Vehicle Mandate, mandating 10% of every van manufacturer’s sales to be BEVs this year, poses challenges. Flatlined BEV market share in 2023 compared to 2022 highlights the need to align LCV demand with supply, necessitating immediate action to address barriers to BEV uptake, particularly the shortage of van-suitable public chargers. A sustained commitment to the Plug-in Van Grant is essential for facilitating a seamless transition across all sectors and regions of the country.

Vehicle importer of luxury cars Clive Sutton has launched a new premium conversion of the Mercedes-Benz Sprinter.

Called the VIP Class Sprinter it has seating for up to nine people with leather-clad seating, twin 40-inch 4k screens and even two fridges. There’s also a surround sound cinema system.

The revamped Sprinter has seven padded saloon chairs, and because it is based on the high roof model has more than two metres of headroom thanks to the generous Sprinter dimensions.

Options for the posh van include anything from coffee machines to a full washroom with hand basin and flushing toilet. The rear space can also be fitted-out with a full-size wardrobe.

Prices will start from from £180,000 plus VAT. Additional equipment, however, will surely see the price of many reach eye-watering numbers in the realms of many of the supercars that Sutton is known for selling. The VIP Class Sprinter will be available with a huge selection of options from heated seats throughout to a high-power air conditioning system.

For those that are conscious that they are in the rear of a van, a twin-section panoramic glass roof ( or a triple-section on the extended wheelbase Sprinter) will also be available.

Fitted with dark privacy glass as standard, Sutton says it is ideal for business meetings thanks to its HDMI integration for the 4K smart screens, or as party transport with its full audio system, mood lighting, and dual drinks fridge compartments.

Clive Sutton, Founder and CEO: “Our customers demand the absolute pinnacle of luxury, refinement, comfort, and practicality, so we’ve pulled out all the stops to make our 2024 VIP Class Mercedes-Bens Sprinter the most luxurious, spacious, and stylish way to transport up to nine people in absolute comfort.”

In addition to its Sprinter-based people mover, there is also the possibility of having a bespoke people carriers based on the Mercedes-Benz Vito van.

All vehicles are fully-homologated and available as ‘built-to-order’ or ‘pre-configured’ versions to customers across the UK and come with a three-year warranty on both the vehicle and the conversions.

Estimates vary but more than two thirds of the world’s populations will be living in cities by 2050 – an increase of 13%, equating to roughly 1bn more people. As things stand, this poses a number of issues not least for air quality and noise pollution as scores of vehicles flood the cities to meet our needs whether it is for construction materials and equipment or goods for home delivery and healthcare.

While much of the urban population growth is expected in countries such as India, China and Nigeria, Europe and the UK are reacting to the role transport plays in pollution levels and are introducing stricter emission targets in cities and placing restrictions on the types of vehicles that will be allowed to enter the cities to counteract the rise.

Electrification is becoming a high priority for governments and fleets alike, but how will building materials, your weekly food shop and critical temperature vaccines all be moved about the urban environment. There’s now a growing need for converted electrified vehicles capable of moving such items and just like with combustion engine products it will be chassis cab vans from bodybuilders that will be filling the void.

“We’re constantly electrifying our vans, and we always keep an eye on our customer requirements. The requirements regarding bodies and conversion are as diverse as the sectors that use them,” explains Markus Reis, Mercedes-Benz Vans product manager.

While there are no limitations as to where an electric vehicle might be used and what sectors are likely to operate them first, blue chip companies are leading the way and it’s no surprise that the booming home delivery segment is a willing customer.

“We have both N1 and N2 vans of the E Deliver 9 being built for Tesco,” explains Mark Barrett, MAXUS general manager. Having already supplied chassis cab versions of its previous generation large electric van, the EV80, to a number of fleets, MAXUS has been able to develop their new E Deliver 9 model to better cope with the demands imposed by fridge units, tail lifts and other auxiliary equipment.

“One of the things for us, is the early planning with the customer at how we integrate the fridge and the base vehicle together. We engage with the factory, and we have 3kW to 5kW of additional spare power from the battery which is going through a controller unit, and the fridge connects to that. For other auxiliary equipment, like tail lifts, it can come from the standard 12v battery,” explains Barrett.

Not all manufacturers will permit a direct power feed from the traction battery, which can lead to having separate power supplies in addition to the 12v battery to run ancillary devices, however, for the most part the power consumption of the equipment is either relatively low, or confined to short bursts.

“Of course it impacts on the range,” continues Barrett, “but surprisingly very little. On maximum drawdown you’re looking at 10 to 15 minutes to get it down to chill or frozen. That will probably done while still on charge and once its down to temperature it doesn’t take much [to maintain the temperature]. Heating the cabin of the van will in theory use more van than the fridge.”

Veteran of the electric light commercial vehicle market Renault, whose Master ZE large van has recently been rebranded as the Renault Master E-Tech, already has an electric Luton low-loader van on sale and is, according to Renault LCV conversions manager Mark Waite, experimenting with other prototype bodies and battery top-up solutions.

“The only complexity we have with electric vehicles is how you treat electrical connections because it’s forbidden to take any electrical connections off of the Master’s traction battery. You still have the 12v electrical system to connect to, so the question is when do you connect to that [or a separate supply]. We’ve prototyped a ZE tipper and will go into a test phase to see what impact it has on range. We’re not expecting it to have a dramatic effect because the electrical draw for raising a tipper bed happens for a 20-second blast. Putting a tail lift on a Luton box van, you’ve got the same issue where the electrical draw would impact the range of the vehicle. In that instance, we’re doing a trial with fitting solar panels to the roof to assist in making sure the main 12v battery is topped up, because in reality you’re going to use a tail lift more than a tipper.”

Manufacturers are in fact already working on a solution for more power-hungry equipment with both Iveco and the Stellantis brands confirming to Van Reviewer that they are working on electric PTO solutions for their eLCVs.

“We’ve been working with bodybuilders for about two years,” says Mike Cutts, Iveco business line director (LCV) about the 2022 model-year electric Daily van.

“We will focus on the chassis models with an electric PTO offer, making sure there’s enough transferable power to meet the applications whatever you want to put on the back,” Cutts explains.

Presently, however, Stellantis bodybuilder relations manager, Hervé Criquy, believes that the vehicle’s main battery can be used to power most equipment and with only a small decrease in range from the equipment’s power draw. “We believe the HV (high voltage) battery can supply enough power to any conversion appliance, without major impact on the range due to the consumption. For example with fridge solutions, the impact of a normal delivery round trip shall be of -5 to -8% on the range,” Criquy says.

When it comes to limitations on what body can be applied to an electric van both Barrett and Waite believe there are actually no limits. With the exception of the placement of battery cells if they’re located within areas a bodybuilder would want to drill in to for mounting, neither sees any issues – a point which Mercedes has ably demonstrated by converting an ambulance on to an Mercedes-Benz eSprinter chassis.

“The industry is quite good at thinking how to overcome potential drawbacks with electric systems. If you think of refrigerated vehicles, the refrigerated vehicle industry has developed its own lithium-ion battery systems to power electrical refrigeration units,” Waite says.

Barrett agrees, and goes so far as to say that electric versions can outperform their diesel equivalents.

“I think any of the applications on a diesel would work on electric. Even when it comes to van payloads as we have that flexibility in the UK with the uprated payload. It has killed that issue. We’re plated at 4050kg on the N2, so you’ve actually got a better payload.”

Vehicle range, reduced payload and invariably the purchase cost may all be valid areas of concern for potential electric van purchasers, but when it comes to equipping this new era of vehicles with the bodies and equipment we’ve become accustomed to there’s no reason to be alarmed. Indeed, as technology improves, the efficiency and productivity of these vans may well see bodied EVs becoming more practical and cheaper to run than their ICE equivalents.

How to build onto an electric van chassis

Like with any build its best to read the instructions. Manufacturers provide their partners with details technical documents and these should be your first port of call. An accredited body builder is best placed to do the work. If in doubt, consult the experts.

The priority is to not damage the safety cell of the vehicle or its battery. Many electric vehicles have defined points where bodies, cranes or tail lifts can be fixed to. These will likely be the same position as any ICE equivalent vehicle.

If adding additional powered equipment don't assume you can use the van's own electrical system. Some vans will make provisions for you to tap into an electricity supply, other won't. More power hungry devices might require a Power Take Off unit and ePTOs are becoming increasingly common.

The hidden costs of electrification are well documented, and we’re not talking about the nasty shock from your energy supplier when the monthly statement lands. Extracting rare raw materials from the earth using methods that not only scar the landscape but often pollute local water courses and other vital animal habitats has long been the secret shame of our quest for Net Zero.

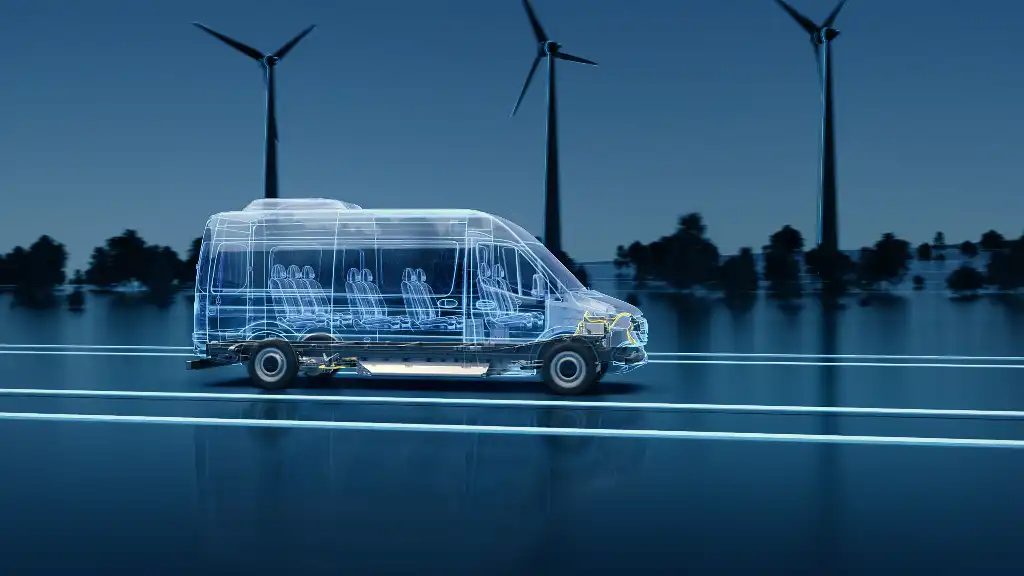

Doing so in some of the most impoverished countries in the world with a labour force too young to attend your nearest high school has been another stain on the business of building batteries whether they’re for electric vehicles or consumer electronics. Like all large companies, Mercedes-Benz knows this and as a result its latest Mercedes-Benz eSprinter will be free from cobalt and nickel to lessen the impact of its production but as a whole the brand is pushing towards a cleaner future. The Ambition 2039 sustainable business strategy is an overarching aim to make its car and van production CO2 neutral over the entire life of the vehicle. That means a fully electrical vehicle that has had its entire CO2 output in production either neutralised or offset.

The vision begins in earnest in 2025, when all newly launched vehicles will be electric only, but the process has in fact already begun with electric versions of all models now present in the range. Mercedes estimates the total investment in electric vehicles between 2022 and 2030 will surpass €40bn.

There reductions in CO2 begin at the point of manufacture where steps have already been taken to produce CO2 neutral vehicles with new plants designed to allow this using innovative energy concepts including photovoltaic systems, DC power grids and energy storage systems based on reused vehicle batteries.

“We talk about our own green electricity efforts in our production for example. We are already CO2 neutral this year, but of course not totally without doing a [CO2 offset] contribution where we are not capable to do it otherwise. But by increasing the green energy production on site ourselves, we can get those substitutions in other ways, getting emissions down and being like real CO2 neutral in our in our production,” explains Marcel Minter, Mercedes-Benz Vans head of business and product strategy.

“What is the crucial part for us is that our vans are actually shaping the cityscape. We are aware that our vehicles are important in terms of mobility but many people just think of them as courier and parcel vehicles. If you look at those vehicles, we have refrigerated, bringing goods to restaurants and kindergartens, we have ambulances, we vehicles taking engineers to your house to repair your washing machine. We are talking a lot about banning vehicles from the city, but we say that's not the solution – at least not for our vans, because we believe strongly in individual mobility and we want to contribute to that. We want to show what is already possible today and what will be possible in the future because our vans have a role to play,” Minter continues.

From harvesting solar energy on production site roofs, through to recycling everything from wastewater to giving batteries a second life, Mercedes-Benz Vans is looking to minimise its environmental impact and utilise self-made green energy, whilst still producing a vehicle that meets the demands of its customers.

A recent technological study vehicle called the Mercedes-Benz Sustaineer (a portmanteau of ‘sustainability’ and ‘pioneer’) explored the numerous possibilities of a greener Sprinter van.

From its cast iron brakes with a ceramic coating to reduce the amount of fine particulate emissions, to its use of sustainable materials (natural straw) in the bulkhead, Mercedes is thinking outside of the box for future materials and their applications. The concept also underlines the fact that improving city air quality will not come from emissions alone.

“We wanted to show that sustainability is much more than just EVs and CO2 reduction,” continues Minter. “We took the current Sprinter as the technical basis and we have added a lot of sustainable features in it to make that tangible. We have for example, just a simple one, added shelfing in the back, as the use case was for a courier and parcel vehicle, out of recycled material. The partner who did that shelving system, they started to think of sustainability in a totally new way with recycled plastic and now they offer their own [sustainable] shelving system. now. We have added solar panel, sustainable fabric and fillings for seats. That's how we think of sustainable logistics in the future.”

While recycled materials and renewable energy make a significant contribution to the production emissions of a vehicle, the ongoing output throughout the life of a van will invariably come under scrutiny. Zero emission vehicles ensure local CO2 emissions are negated but the problem of fine particulates remains and is becoming an increasing problem.

“Of course, another example is the fine dust pollution. Many people think that fine dust is caused by the engine, but it is the brakes, the tyres, and the recirculation from the street. What we did was reduce the fine dust emission of the brakes and the tyres, and then [develop a] systems to the front, into the underbody. By doing so we're capable to filter out between 50% to 200% of its own emissions, depending on the overall pollution. So, if you operate the vehicle in China, the area after it [the van] passed it's cleaner than before. This is awesome and is something we are now figuring out with the Austrian post – where we do a pilot and testing that filter system in real conditions. We wanted to try that in real driving condition. We're now figuring out step-by-step, which one of these ideas makes sense. And if that makes sense, is it a business case? In the end it's about making money, but especially in these sustainability features, we are convinced that they could be a huge differentiator in terms of our competitors. It's a good USP because we are, more or less, the only premier manufacturer in terms of vans and we set the standard over and over again in terms of safety, and in terms of connectivity, for example. Then we want to set the standard again in sustainability,” Minter explains.

While a giant under-bumper vacuum cleaner might sound a little far-fetched as a means of improving air quality, Mercedes is pushing the envelope in trying these things. Their use differing materials and innovative systems does set them apart from competitors. As a premium brand it is looking at ways of maintaining that uniqueness and through developing environmentally friendly and sustainable products it is setting itself apart.

“Perhaps there are some features where we don't make money with the option, but we are the only ones who can offer that to customers and the customers, in terms of sustainability, says okay, that is very important to me. Our target is to get as much sustainable features and materials in as possible, because otherwise we won't reach our Vision 2039. Our main approach is to get as much sustainability in as possible, as standard.”

Is it then possible that in the future we will see specific sustainable editions of Mercedes vans? Minter thinks not, but does concede it is perhaps something that would work in the passenger car market. Instead, for commercial vehicles, he says he would like to see sustainable materials and features being adopted across all models. “There could be a way that you mark those sustainability features. So, some materials that are sustainable, they are then not black, but green. That could be a way that people can show that they are thinking in that direction. But for it to work and be sustainable it has to be incorporated into all of the vans,” he adds.

A truly sustainable van may still be a long way off, but Mercedes is making big steps to improve its net CO2 outputs. From the factory to the product, Mercedes vans are not only speaking about ambitious targets but actively chasing them.

How to build a sustianable van

Mercedes' purpose-built Factory 56 might be being used to build passenger cars, but it lays out the blue print for how clean energy can improve production. The site uses solar panels on its roof and wind turbines in the area around the facility to produce green energy that is sufficienty enough to run the production line.

Waste is the enemy of sustainability. By reducing wasted materials as well as wasted time, the process of building a van has become more efficient. Greater efficiencies mean a more sustainable product.

We all know recycling is hugely important, but using recycled materials in the production of a van is not something you'd automatically think of. Mercedes-Benz Vans has been toying with the idea of using recycled plastic bottles in its vans. The plastic bottles are processed and the spun into a fine thread which is used to weave fabric for the seats. Other initiatives have included using plant-based fibres for items like shelving.

This is the big one. Remove the combustion engine and all of a sudden the van become less polluting over its lifespan. Providing the energy used to charge electric batteries is green, adopting electric drivetrains (and in future hydrogen, also produced from green energy) will see vans become much more sustainable across their life.